|

Manufacturing process |

|

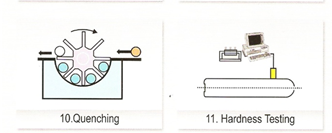

Hardness testing |

|

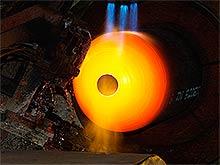

Quenching |

|

Tempering |

|

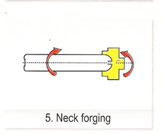

Neck forging |

|

Bottom forging |

|

Cutting |

|

Tubes |

|

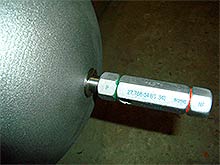

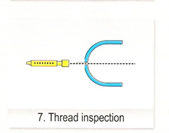

Thread inspection |

|

Weighing and measuring capacity |

|

Neck machining and threading |

|

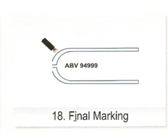

Final Marking |

|

Hardness Check |

|

Hydraulic Test |

|

Internal and external shot blasting |

|

Painting |

|

13. Internal and ext shot blasting |

|

17. Packing |

|

16. Assembling of accesories |

|

14. Final marking |

|

15. Painting |

|

10. Thread inspection |

|

11. Weighing |

|

12. Hydraulic test |

|

7. Tempering |

|

8. Hardness Check |

|

9. Neck machining and threading |

|

4. Neck forging |

|

5. Quenching |

|

6. Hardness Testing |

|

2. Cutting |

|

3. Bottom forging |

|

1. Tubes |

|

PRODUCTIONS PROCESS |

|

QualiTy control |

|

INPROCIL cylinders are compliant with the highest national and international safety and reliability standards supported with ISO, IRAM, NZS, COVENIN certifications and the most stringent official approvals for industrial products and processes granted by Bureau Veritas, a Certifying Authority.

|

|

INPROCIL CYLINDERS |

|

Home |

|

Company Profile |

|

Draws and Measures |

|

Products |

|

Our Laboratories |

|

Manufacturing process |

|

Certificates Test |

|

Raw Material CrMo |

|

Contact |

|

Certificates of Approval |